Vesi, õli, seep, AdBlue täitmismasinPROTON EE-ELEKTRONIKA d.o.o

XFR1000

Vesi, õli, seep, AdBlue täitmismasin

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Tootmisaasta

2025

Seisund

Uus

Asukoht

Šašinovec

Pildid näitavad

Kuva kaart

Andmed masina kohta

- Masina nimetus:

- Vesi, õli, seep, AdBlue täitmismasin

- Tootja:

- PROTON EE-ELEKTRONIKA d.o.o

- Mudel:

- XFR1000

- Tootmisaasta:

- 2025

- Seisund:

- uus

- Töövõimekus:

- täielikult töökorras

Hind ja asukoht

- Asukoht:

- Krcevina 4, 10360 Soblinec, Hrvatska

Helistada

Tehnilised andmed

- Kogulaius:

- 2 400 mm

- Kogupikkus:

- 15 000 mm

- Kogukõrgus:

- 2 800 mm

- Rõhk:

- 8 latt

- Võimsus:

- 10,9 kW (14,82 hj)

- Tühimass:

- 6 400 kg

- Sisendpinge:

- 400 V

- Täitekaal (min.):

- 200 g

- Täitmismass (max.):

- 5 000 g

Pakkumise üksikasjad

- kuulutuse ID:

- A17231422

- Värskendus:

- viimati kuupäeval 25.09.2025

Kirjeldus

XFR 1000

Liquid Media Filling Line

Ijdpfxeuq Nv Ts Abfsal

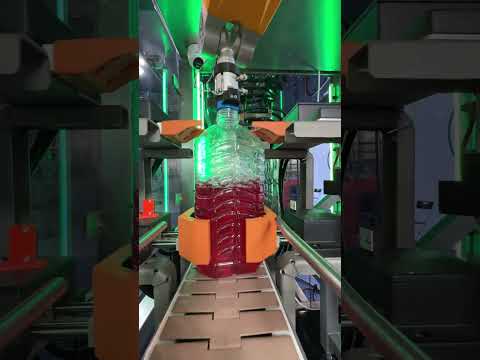

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

Ijdpfxeuq Nv Ts Abfsal

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Dokumendid

Pakkuja

Märkus: Registreeru tasuta või logi sisse, et saada kogu teave.

Registreeritud alates: 2020

Saada päring

Telefon & Faks

+385 43 3... kuulutused

Need kuulutused võivad samuti teile huvi pakkuda.

Väike kuulutus

Italia

Italia

2 054 km

Jookide tootmise masin

Canning KHS Line Bottling 25.000 cphCans Complete Canning KHS 2017

Canning KHS Line Bottling 25.000 cphCans Complete Canning KHS 2017

Väike kuulutus

Skarżysko-Kamienna

Skarżysko-Kamienna

872 km

Demineraliseeritud veejaam

ROMERRDI-2 / RDI-4

ROMERRDI-2 / RDI-4

Väike kuulutus

Schorfheide

Schorfheide

954 km

Statsionaarne segamisjaam

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Väike kuulutus

Neckartailfingen

Neckartailfingen

1 515 km

Tolmu väljatõmbesüsteemiga pallimasin

mütek

mütek

Väike kuulutus

Nijverdal

Nijverdal

1 354 km

Kemper ST75 A

KemperSt75 A

KemperSt75 A

Väike kuulutus

Rīga

Rīga

197 km

Automaatne kapsasüdamik KU-2400

Alistar EuropeKU-2400

Alistar EuropeKU-2400

Väike kuulutus

Tata

Tata

1 298 km

Eksentrikpress AIDA NC2-250, 250 tonni

AIDA NC1-250250ton

AIDA NC1-250250ton

Väike kuulutus

Iirimaa

Iirimaa

2 152 km

Kasseti Filline liin

Coffee Cartridge Filling & Packaging Lin€ 10,000 Euro

Coffee Cartridge Filling & Packaging Lin€ 10,000 Euro

Väike kuulutus

Δράμα

Δράμα

1 943 km

Offset trükkimise tüüp

ShinoharaSHINOHARA 75

ShinoharaSHINOHARA 75

Väike kuulutus

Rīga

Rīga

190 km

Ühepealine lõikemasin

OMCRONDA 700

OMCRONDA 700

Teie kuulutus on edukalt kustutatud

Ilmnes viga