KlassifitseerimisveskiHosokawa Alpine

ZPS 315

Klassifitseerimisveski

Hosokawa Alpine

ZPS 315

tootmisaasta

1991

Seisund

Kasutatud

Asukoht

Augsburg

Pildid näitavad

Kuva kaart

Andmed masina kohta

- Masina nimetus:

- Klassifitseerimisveski

- tootja:

- Hosokawa Alpine

- Mudel:

- ZPS 315

- tootmisaasta:

- 1991

- Seisund:

- kapitalne remonditud (kasutatud)

Hind ja asukoht

- Asukoht:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

Helistada

Pakkumise üksikasjad

- kuulutuse ID:

- A9622523

- värskendus:

- viimati kuupäeval 10.02.2025

Kirjeldus

Used Hosokawa Alpine Zirkoplex ZPS 315 classifier mill

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Use of original components only

Original manufacturer warranty

Guaranteed manufacturer spare parts supply

Short lead time

Before delivery, the machine is overhauled, all wear parts are revised and exchanged if needed and customized to your specific needs

Possibility to provide all additionally required peripherals or adapt to existing production plant

We are also interested in buying back disused HOSOKAWA ALPINE machinery

Ibedpfslgy U Njx Aaaoc

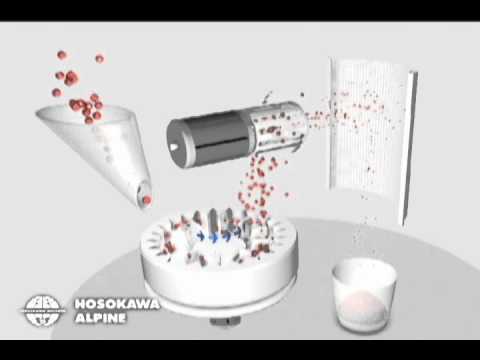

The Hosokawa Alpine Zirkoplex ZPS impact classifier mill is perfect for the fine grinding of different dry materials with a precise control over the particle´s top cut thanks to its integrated classifier wheel design, using the Alpine classifier ATP. It can be used to pulverize different products and within different industries where micronization might be needed, such as minerals, chemicals, food, pharma, etc. The comminution takes place in the bottom part of the grinding chamber where the rotor plate fitted with grinding tools (hammers or pins) impacts and projects the particles against the liner in order to break them. Within the same chamber, the air circulation brings the fines to the rotating classifier wheel where oversize grains are rejected to then return to the griding zone for reprocessing, whereas the fine particles make it through the classification step to the next stage, normally the filter. Thanks to the required process air volume, reduced temperature increase during grinding is to be expected compared to other granulation technologies. Adjusting the final particle size distribution can be easily done by changing different parameters, such as the speed of the grinding rotor or disc and the classifier wheel, air volume, feeding rate, etc.

Material of construction: mild steel

Without wear protection

Non Pressure Shock Resistant (NPSR), non-ATEX

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, a set of grinding tools of choice and installation table

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Use of original components only

Original manufacturer warranty

Guaranteed manufacturer spare parts supply

Short lead time

Before delivery, the machine is overhauled, all wear parts are revised and exchanged if needed and customized to your specific needs

Possibility to provide all additionally required peripherals or adapt to existing production plant

We are also interested in buying back disused HOSOKAWA ALPINE machinery

Ibedpfslgy U Njx Aaaoc

The Hosokawa Alpine Zirkoplex ZPS impact classifier mill is perfect for the fine grinding of different dry materials with a precise control over the particle´s top cut thanks to its integrated classifier wheel design, using the Alpine classifier ATP. It can be used to pulverize different products and within different industries where micronization might be needed, such as minerals, chemicals, food, pharma, etc. The comminution takes place in the bottom part of the grinding chamber where the rotor plate fitted with grinding tools (hammers or pins) impacts and projects the particles against the liner in order to break them. Within the same chamber, the air circulation brings the fines to the rotating classifier wheel where oversize grains are rejected to then return to the griding zone for reprocessing, whereas the fine particles make it through the classification step to the next stage, normally the filter. Thanks to the required process air volume, reduced temperature increase during grinding is to be expected compared to other granulation technologies. Adjusting the final particle size distribution can be easily done by changing different parameters, such as the speed of the grinding rotor or disc and the classifier wheel, air volume, feeding rate, etc.

Material of construction: mild steel

Without wear protection

Non Pressure Shock Resistant (NPSR), non-ATEX

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, a set of grinding tools of choice and installation table

Pakkuja

Märkus: Registreeru tasuta või logi sisse, et saada kogu teave.

Registreeritud alates: 2019

Saada päring

Telefon & Faks

+49 821 2... kuulutused

Need kuulutused võivad samuti teile huvi pakkuda.

väike kuulutus

Augsburg

Augsburg

1 470 km

Klassifitseerimisveski

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

väike kuulutus

Arnsberg

Arnsberg

1 344 km

Klassifitseerija veski

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

Teie kuulutus on edukalt kustutatud

Ilmnes viga