Hüdrauliline pressHidrogarne

CF-400E/NC

Hüdrauliline press

Hidrogarne

CF-400E/NC

Seisund

Kasutatud

Asukoht

Bellpuig

Pildid näitavad

Kuva kaart

Andmed masina kohta

- Masina nimetus:

- Hüdrauliline press

- Tootja:

- Hidrogarne

- Mudel:

- CF-400E/NC

- Seisund:

- nagu uus (kasutatud)

- Töövõimekus:

- täielikult töökorras

Hind ja asukoht

- Asukoht:

- Hostal Nou 2, 25250 Bellpuig, Spanien

Helistada

Tehnilised andmed

- Pressimissurve:

- 400 t

- Laua laius:

- 2 000 mm

- Laua pikkus:

- 1 000 mm

- Töötamiskiirus:

- 106 mm/s

- Tagurpidikiirus:

- 125 mm/s

- Käigupikkus:

- 750 mm

- Pressimiskiirus:

- 12 mm/s

- Varustus:

- turvakiirgusbarjäär

Pakkumise üksikasjad

- kuulutuse ID:

- A19154651

- Viitenumber:

- CF-400E/NC

- Värskendus:

- viimati kuupäeval 13.10.2025

Kirjeldus

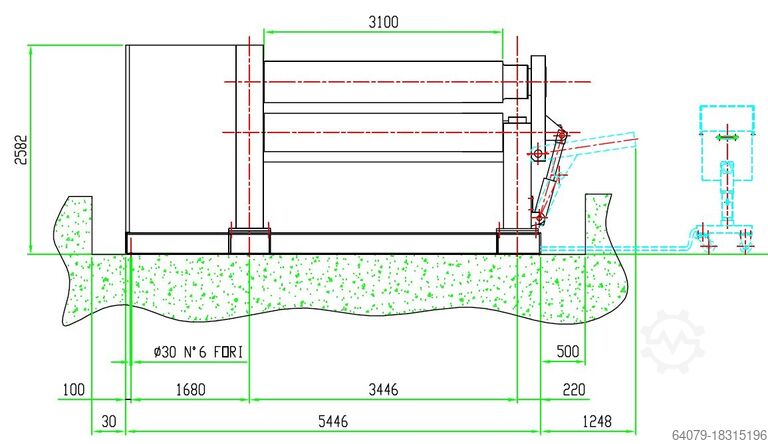

HYDRAULIC C-FRAME PRESS FOR RAILWAY RAIL STRAIGHTENING

We are offering a new/replica version of this press.

The press will be placed on sale by the customer in the second or third quarter of 2026 due to the project's extension.

The CF-400E/NC hydraulic press belongs to the CF/NC series and was specifically designed for railway rail straightening.

Equipped with an upper and lower table made of machined C45E steel with DIN 650 grooves.

It uses an optimized hydraulic system with a pressure of less than 255 bar, ensuring long service life and reliable performance.

It meets all essential health and safety requirements according to CE regulations.

TECHNICAL DATA

Press force T 400

Motor power kW 22

Variable working speed mm/s 4-12

Approach speed mm/s 106

Return speed mm/s 125

Maximum pressure bar 255

Stroke mm 750

Lower table mm 2,000 x 1,000

Push plate mm 2,000 x 1,000

Maximum vertical clearance mm 1,000

Working height mm 960

Total height mm 3,560 + 600

Weight kg 39,500

STRUCTURE AND TABLE:

• The gooseneck structure is electro-welded and made entirely of S355JR steel.

• Stabilized and machined at the end of the welding process to ensure perfect parallelism and precision.

• Calculated and designed using finite element software.

• The upper table ensures perfect alignment with four 80 mm diameter lateral cylindrical guides equipped with maintenance-free bimetallic bushings.

CYLINDERS AND HYDRAULIC GROUP

• Single-acting main cylinder with jacketed barrel, chrome-plated piston, and maintenance-free, wear-resistant guides.

• Two lateral double-acting cylinders with chrome-plated pistons and wear-resistant guides, enabling fast start-up and return speeds.

• Includes two independent hydraulic safety blocks.

• Motorized hydraulic group with pre-fill valve for forward and reverse flow. Constant power, variable flow pump.

• Equipped with a directional control valve, a pressure relief valve, a decompression valve, and an air-oil cooling system.

• Glycerin pressure gauge with tonnage indicator.

ELECTRICAL INSTALLATION AND SAFETY

• Includes a SIEMENS safety PLC, model SIMATIC S7 1200, and a 7-inch touchscreen, model KTP-700 CONFORT, located in the control cabinet. It allows programming of semi-automatic and automatic operating modes, power, stroke, and dwell time. It has a memory capacity of 300 recipes, with each recipe capable of programming all previous values.

• Electrical and hydraulic maneuvers are redundant and self-controlled. It includes an additional safety block and self-checking devices for maneuvers and safety. It includes verification and certification of correct operation and the safety distance for photocells.

• Operation is via a low-voltage electric pedal.

• For safety, lasers and work area protection with Category IV photoelectric barriers are integrated.

Nkjdpjwkv A Nsfx Abdou

Kuulutus tõlgiti automaatselt. Tõlkevigu võib esineda.

We are offering a new/replica version of this press.

The press will be placed on sale by the customer in the second or third quarter of 2026 due to the project's extension.

The CF-400E/NC hydraulic press belongs to the CF/NC series and was specifically designed for railway rail straightening.

Equipped with an upper and lower table made of machined C45E steel with DIN 650 grooves.

It uses an optimized hydraulic system with a pressure of less than 255 bar, ensuring long service life and reliable performance.

It meets all essential health and safety requirements according to CE regulations.

TECHNICAL DATA

Press force T 400

Motor power kW 22

Variable working speed mm/s 4-12

Approach speed mm/s 106

Return speed mm/s 125

Maximum pressure bar 255

Stroke mm 750

Lower table mm 2,000 x 1,000

Push plate mm 2,000 x 1,000

Maximum vertical clearance mm 1,000

Working height mm 960

Total height mm 3,560 + 600

Weight kg 39,500

STRUCTURE AND TABLE:

• The gooseneck structure is electro-welded and made entirely of S355JR steel.

• Stabilized and machined at the end of the welding process to ensure perfect parallelism and precision.

• Calculated and designed using finite element software.

• The upper table ensures perfect alignment with four 80 mm diameter lateral cylindrical guides equipped with maintenance-free bimetallic bushings.

CYLINDERS AND HYDRAULIC GROUP

• Single-acting main cylinder with jacketed barrel, chrome-plated piston, and maintenance-free, wear-resistant guides.

• Two lateral double-acting cylinders with chrome-plated pistons and wear-resistant guides, enabling fast start-up and return speeds.

• Includes two independent hydraulic safety blocks.

• Motorized hydraulic group with pre-fill valve for forward and reverse flow. Constant power, variable flow pump.

• Equipped with a directional control valve, a pressure relief valve, a decompression valve, and an air-oil cooling system.

• Glycerin pressure gauge with tonnage indicator.

ELECTRICAL INSTALLATION AND SAFETY

• Includes a SIEMENS safety PLC, model SIMATIC S7 1200, and a 7-inch touchscreen, model KTP-700 CONFORT, located in the control cabinet. It allows programming of semi-automatic and automatic operating modes, power, stroke, and dwell time. It has a memory capacity of 300 recipes, with each recipe capable of programming all previous values.

• Electrical and hydraulic maneuvers are redundant and self-controlled. It includes an additional safety block and self-checking devices for maneuvers and safety. It includes verification and certification of correct operation and the safety distance for photocells.

• Operation is via a low-voltage electric pedal.

• For safety, lasers and work area protection with Category IV photoelectric barriers are integrated.

Nkjdpjwkv A Nsfx Abdou

Kuulutus tõlgiti automaatselt. Tõlkevigu võib esineda.

Pakkuja

Märkus: Registreeru tasuta või logi sisse, et saada kogu teave.

Registreeritud alates: 2025

Saada päring

Telefon & Faks

+34 973 3... kuulutused

Need kuulutused võivad samuti teile huvi pakkuda.

Väike kuulutus

Gelsenkirchen

Gelsenkirchen

1 375 km

Hüdrauliline press

HidrobrasilDoppelständerpresse 400 Tonnen

HidrobrasilDoppelständerpresse 400 Tonnen

Väike kuulutus

Mudersbach

Mudersbach

1 389 km

Ümmargune painutusmasin

Isitan4R HMS 1270 x 130

Isitan4R HMS 1270 x 130

Väike kuulutus

Ciriè

Ciriè

1 897 km

Hüdrauliline press

MOSSINIPO/2M/P2000

MOSSINIPO/2M/P2000

Väike kuulutus

Babberich

Babberich

1 402 km

Hüdrauliline vormimisõue Press 1000 T

URSVIKENVPF 1000

URSVIKENVPF 1000

Väike kuulutus

Cesena

Cesena

1 830 km

ümbertõmbepingid

MG3ROLL3000X50MM

MG3ROLL3000X50MM

Väike kuulutus

Bellpuig

Bellpuig

2 523 km

Sirgenduspress

HidrogarneSH-250

HidrogarneSH-250

Väike kuulutus

Root

Root

1 688 km

CNC EDM masin

AGIE CHARMILLESAC CLASSIC V2

AGIE CHARMILLESAC CLASSIC V2

Väike kuulutus

Bellpuig

Bellpuig

2 523 km

Hüdrauliline press

Hidrogarne/GarnetMV-800/NC SINCRO

Hidrogarne/GarnetMV-800/NC SINCRO

Väike kuulutus

Deinze

Deinze

1 609 km

Horisontaalsed pressid

Van De GraafHHS 400 ton

Van De GraafHHS 400 ton

Väike kuulutus

Austria

Austria

1 315 km

4 tubakarullid, hüdrauliline painutamine

KK-IndustriesCY4R-HHS 510-30/45

KK-IndustriesCY4R-HHS 510-30/45

Teie kuulutus on edukalt kustutatud

Ilmnes viga