Lame matriks, kuumstantsimine, multiGRAFOTRONIC

350 200254G

Lame matriks, kuumstantsimine, multi

GRAFOTRONIC

350 200254G

VB lisandub käibemaks

67 500 €

Seisund

Kasutatud

Asukoht

Kruszyn Krajeński

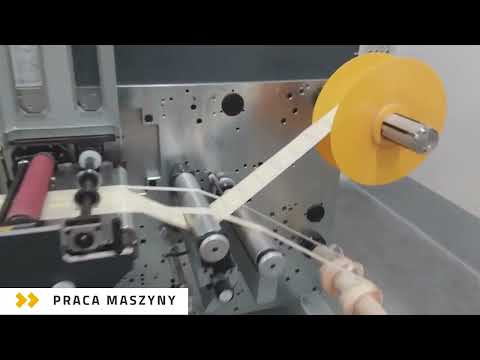

Pildid näitavad

Kuva kaart

Andmed masina kohta

- Masina nimetus:

- Lame matriks, kuumstantsimine, multi

- Tootja:

- GRAFOTRONIC

- Mudel:

- 350 200254G

- Seisund:

- väga hea (kasutatud)

- Töövõimekus:

- täielikult töökorras

Hind ja asukoht

VB lisandub käibemaks

67 500 €

- Asukoht:

- Ceramiczna 15, 86-005 Białe Błota, PL

Helistada

Pakkumise üksikasjad

- kuulutuse ID:

- A18949116

- Värskendus:

- viimati kuupäeval 29.12.2025

Kirjeldus

Segment I – Unwinder with stabilizing table

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Kljdpfxowck U Rj Abfol

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Kuulutus tõlgiti automaatselt. Tõlkevigu võib esineda.

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Kljdpfxowck U Rj Abfol

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Kuulutus tõlgiti automaatselt. Tõlkevigu võib esineda.

Pakkuja

Märkus: Registreeru tasuta või logi sisse, et saada kogu teave.

Registreeritud alates: 2020

Saada päring

Telefon & Faks

+48 52 37... kuulutused

Need kuulutused võivad samuti teile huvi pakkuda.

Väike kuulutus

Emskirchen

Emskirchen

1 368 km

Sisestusmasin

Fracotyp-PostaliaFPi 4530

Fracotyp-PostaliaFPi 4530

Väike kuulutus

Budaors

Budaors

1 303 km

A3 värviline koopiamasin

Konica MinoltaC558

Konica MinoltaC558

Väike kuulutus

Sloveenia

Sloveenia

1 481 km

Pöördtüüblõikus pideva virnastajaga

RIETSTACKIRS 430

RIETSTACKIRS 430

Väike kuulutus

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1 417 km

Digitaalne trükimasin

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

Väike kuulutus

München

München

1 461 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

Väike kuulutus

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1 513 km

FGT Graphic Machinery - Töötlemine

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

Väike kuulutus

Bad Kreuznach

Bad Kreuznach

1 470 km

Flexograafiline trükimasin

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

Väike kuulutus

Kaunas

Kaunas

415 km

Rewer

Jurmet

Jurmet

Väike kuulutus

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1 513 km

FGT Graphic Machinery - Töötlemine

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

Väike kuulutus

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1 513 km

FGT graafilised masinad - Labelfinisher

ROTOFLEXR 1300

ROTOFLEXR 1300

Teie kuulutus on edukalt kustutatud

Ilmnes viga